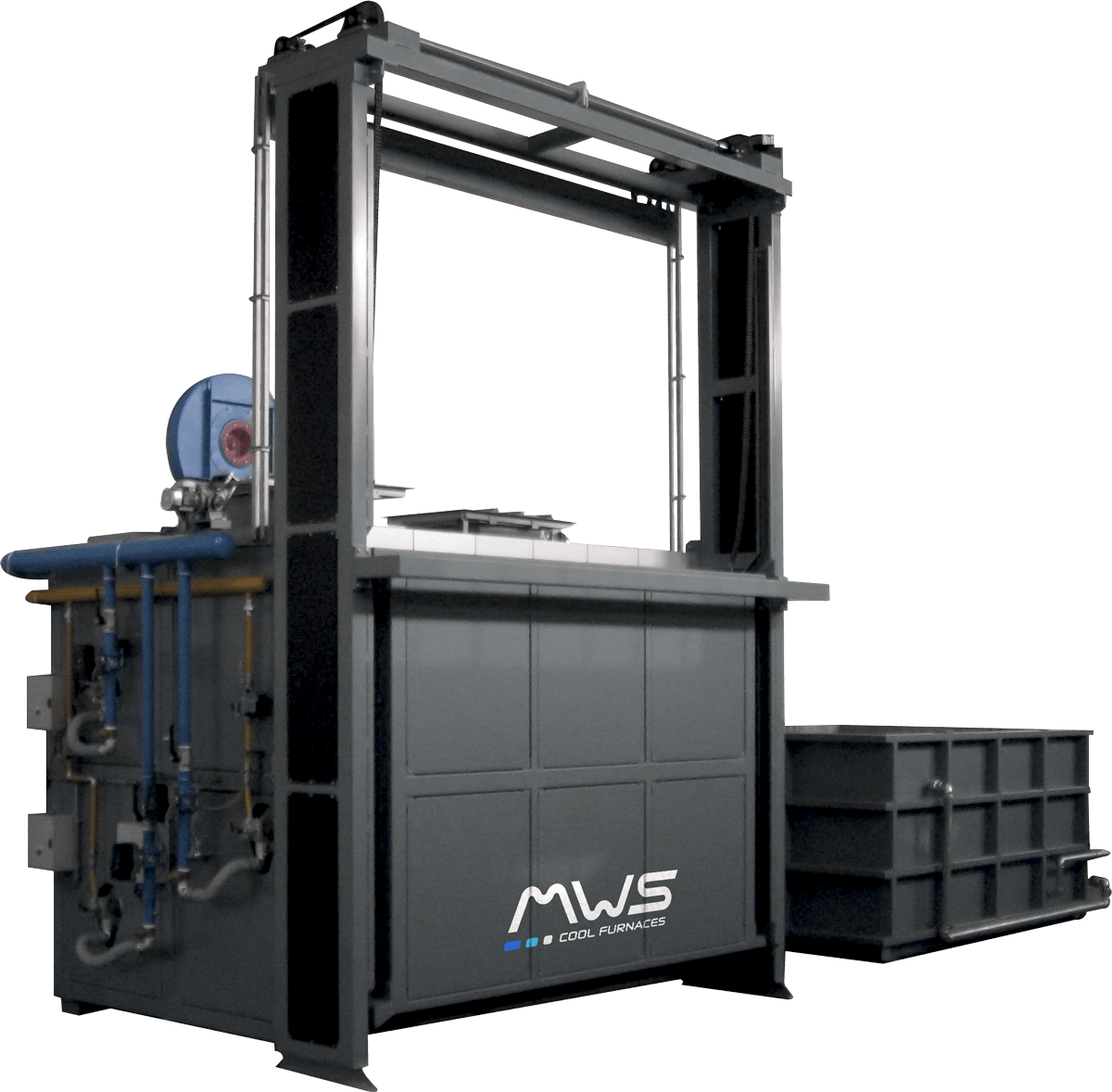

Static Industrial furnaces

The static furnace has a fixed structure. The material goes inside through a door, placed on one of the sides.

Working Temperatures

Capacity

Energy efficiency class

2/5 AMS 2750 from +/- 6 C° to +/- 14 C°

The static furnaces have a fixed floor, the material is positioned inside manually or with the use of cranes, forklifts or dedicated robots. The heating is achieved with gas or electricity, with burners, radiant tubes or resistances.

Structure's description

The structure of Our static furnaces is made of solid steel tubes and profiles. The heating chamber is insulated with ceramic fibres and other refractory material for high temperatures.

The heating is usually achieved with gas burners that ensure a very good energy saving, alternatively with radiant tubes or electrical resistances. The loading and unloading operations are very easy due to the big dimensions of the door. It is possible to install automatic robot for the loading and unloading.

Common heat treatments

Industries

Pros

- Modular structure, developed to follow customer requirements.

- 100% automatable structure and process.

- Easy loading/unloading operations due to large opening

Cons

- Non continuous production.

Customization

- It is possible to develop fully automatic treatment lines, totally customisable to fulfil customer’s requirements.

Features

- Easy loading and unloading operations

- Forced air circulation

- Heating with gas burners/radiant tubes/electrical resistances

- Insulation with refractory materials and ceramic fibre

What you get

Touchscreen panel

Choose the color

Lifetime support

We guarantee lifetime assistance, via phone or email. If your furnace is connected to the internet, we’ll also be able to remotely check the status of the machine and offer a quick and precise diagnostic.

Spare parts for free

CE certification

Made in Italy

Dimensions

What you can get

Remote control

Our furnaces can be connected to the internet. This enables Our technicians to perform a checkup of the machine to guarantee fast and precise diagnosis.

Packaging

You don’t want to think about the packaging? No problem! MWS can do it for You. Our packaging guarantees the maximum safety for road or naval shipments.

Trasport planning

Training

Assembly at your factory

Startup

Digital recorder

MWS furnaces can be equipped with digital recorder to store and print heat treatment reports and graphs, both to store the data and apply certifications to them.